How to Choose a Relay Factory for Quality General Purpose Relays in Electrical Control Systems

Control Devices Technical Specifications for Modern Electrical Control Systems

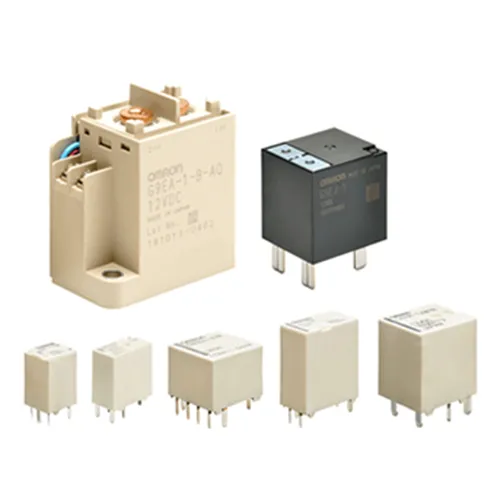

Modern electrical control device increasingly rely on general purpose relay to manage power distribution and system safety. As discussions on Reddit's r/PLC forum highlight, safety relays play a critical role in monitoring redundant circuits like emergency stop buttons and light curtains. These components could ensure machine operation aligns with industrial safety standards, a key consideration for procurement teams evaluating relay factory capabilities.

Operational Advantages of General Purpose Relays

General purpose relay remain indispensable in automation due to their simplicity and reliability, as noted in r/AskEngineers debates. Unlike programmable controllers, relay logic could offer easier debugging and cost-effective solutions for repetitive tasks in electrical control devices. Automotive engineers on r/electrical further emphasize their necessity in vehicle wiring systems, particularly when load currents exceed switch ratings. For procurement professionals, this underscores the value of partnering with a relay factory that prioritizes durability testing and component precision.

Balancing Innovation and Practicality in Manufacturing

A reputable relay factory typically follows stringent production processes, from coil winding to automated assembly. Industry leaders may integrate energy-efficient designs—such as low-power coils—to align with sustainability goals while maintaining compact form factors. Social media discussions frequently cite "redundancy" and "PLC integration" as trending topics, reflecting buyer interest in relays that complement smart control systems. For instance, safety relays with multi-pole configurations could enhance redundancy in industrial electrical control devices, reducing system downtime.

Key Considerations for Procurement Teams

- Certifications: Ensure relays meet ISO and IEC standards for safety and performance.

- Customization: Partner with factories offering tailored solutions for voltage/current requirements.

- Testing Protocols: Prioritize suppliers conducting thermal cycling and endurance tests.

- Industry-Specific Demands: Automotive and telecom applications may require relays with higher contact ratings.

Reddit users often highlight "versatility" and "ease of integration" as decisive factors when selecting general purpose relays. For example, modular relays with LED indicators could simplify maintenance in complex electrical control devices.

If you are interested in our distribution products and want to discuss a purchase, please contact us.